What can you ask TAS Services to service or maintain?

Heat exchangers, cooling towers, level gauges, jet ejectors, vacuum installations. All in the very best hands at TAS Services. Why? Because of our technical know-how that spans decades, not easily found anywhere else. Because of our quick access to replacement parts. Because of our response speed... regardless of who manufactured your equipment.

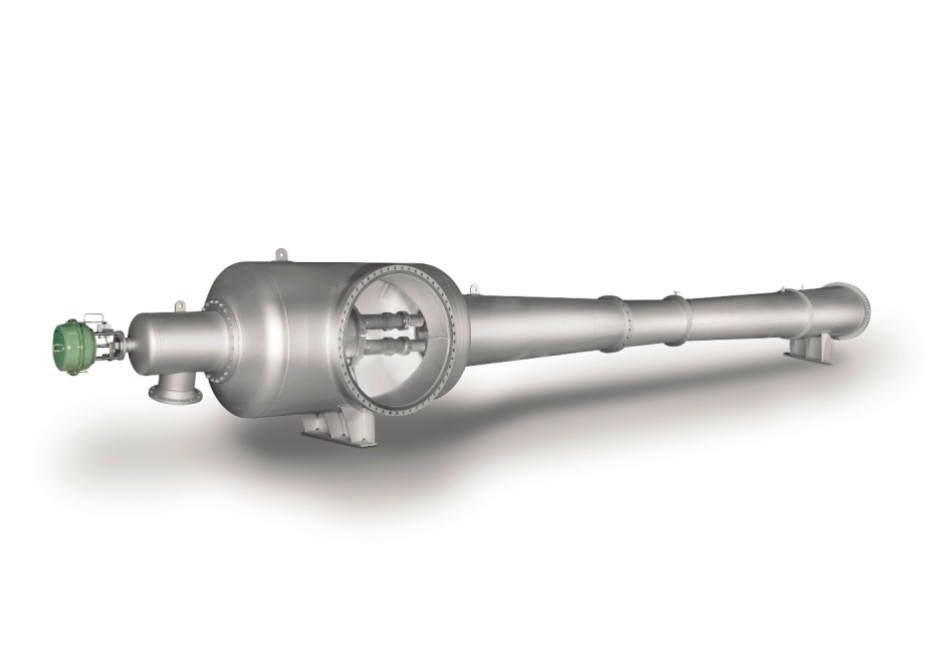

Heat exchangers

Is your heat exchanger no longer cooling properly? Have you noticed a large pressure drop in the installation? Is it leaking, or does it seem clogged? It’s time for maintenance by TAS Services. Re-optimise your processes, so that your HVAC installation once again produces sufficient hot water...

Back to perfect performance from your heat exchanger, in five steps

On-site dismantling: we dismantle your heat exchanger, for an initial visual inspection in situ.

Thorough cleaning: is the heat exchanger clogged up? If yes, we will clean it in our workshop. Exactly to requirements, in line with the type of heat exchanger.

New OEM seals: we install new seals, adapted precisely to the type of heat exchanger.

A pressure test before we finish: our last task is a pressure test, to be certain that the heat exchanger is perfectly sealed.

On-site assembly, after pressure test: we reassemble the heat exchanger on site. All this is done with minimum downtime.

Cooling towers

Is your cooling tower no longer performing as it should, for your processes or the environment? This is something our specialists can help with too - so that your cooling towers can once again achieve optimal cooling for optimal processes. Eliminating the risk of legionella, thanks to excellent mechanical and chemical maintenance.

Back to perfect cooling towers by way of

Visual inspection of your cooling tower: we visually inspect all parts: the interior and exterior cooling packing, the fans, the transmission and motors, the water distribution system, the structure, etc. We prepare a useful report of our findings and also include a quotation for the work required. Without obligation, of course.

Perfect maintenance and perfect repairs: we will repair all repairable mechanical equipment: align the fans, recondition the motor and gearboxes, clean the packs, etc. We use a specialised partner for the chemical maintenance against legionella. If parts and structures need replacing, such as cooling packs and water distribution nozzles, we will take care of the replacement.

Level Gauges

Is your level gauge broken? Does the fluid within look milky (due to damaged mica)? Or do you just want to make sure your level gauges show accurate measurements through preventive reconditioning? Whatever your motivation, you can rely on the expertise on offer at TAS Services. We will make sure your level gauges are perfect level measures once again. For the best possible production, in complete safety.

Back to perfectly reliable level gauges, in five steps

On-site dismantling: if possible, we will recondition the level gauge on site. If not, we will remove it from the tank for reconditioning at our workshop.

Complete overhaul: in the workshop, we completely dismantle the level gauge and inspect every component. Right down to the shut-off valves.

Every necessary replacement: we will replace any part that needs replacing. We rework scratches on the sealing surfaces, making them a perfect fit again.

A pressure test before we finish: our last task is a pressure test, to be certain that the level gauge is perfectly sealed without any leakage.

On-site assembly: the choice is yours: we either have the reconditioned level gauge delivered to you, or we can reassemble it on site ourselves

Jet ejectors & vacuum installations

Is your jet ejector no longer functioning properly? Or does your vacuum installation no longer provide the necessary vacuum? Another job you can leave to TAS Services, for expertise you won’t find anywhere else. Making sure your equipment performs perfectly once again, and your processes are back at optimal levels.

Back to perfect performance from your equipment by way of

Inspection and repair of jet ejector first we visually inspect the jet ejector or corrosion. Then, we dismantle the ejector , to check that the boreholes are still in order. We also check the sealing surfaces for leaks, and the parts for wear and tear, etc. We will use replacement parts wherever necessary.

Vacuum installation troubleshooting: we often start by measuring the vacuum installation’s inlet and outlet to check if the vacuum is up to standard. We use this to determine which parts need replacing. You can either contact the supplier yourself, or we can do it for you.