Process equipment / Level indicators

Level indicators

Level gauges give your operators reliable information about the right level. Whether mechanically or electronically, directly or indirectly, or transparent or bicolour, with or without background illumination, the Igema sight glasses provide you with the correct separation of steam and water or other media.

Igema products are manufactured in accordance with Pressure Equipment Directive 2014/68/EU and designed to the current standard for operating steam boiler units (TRD, AD 2000, ASME Boilers etc.).

TAS has a large stock of spare parts for the IGEMA devices (glasses, mica, seals, floats, magnetic switches and valves).

| Materials: | Staal, RVS |

William Nuyts

Expert in level indicators

Any questions? Let me know.

Product variations

Choose a variation:

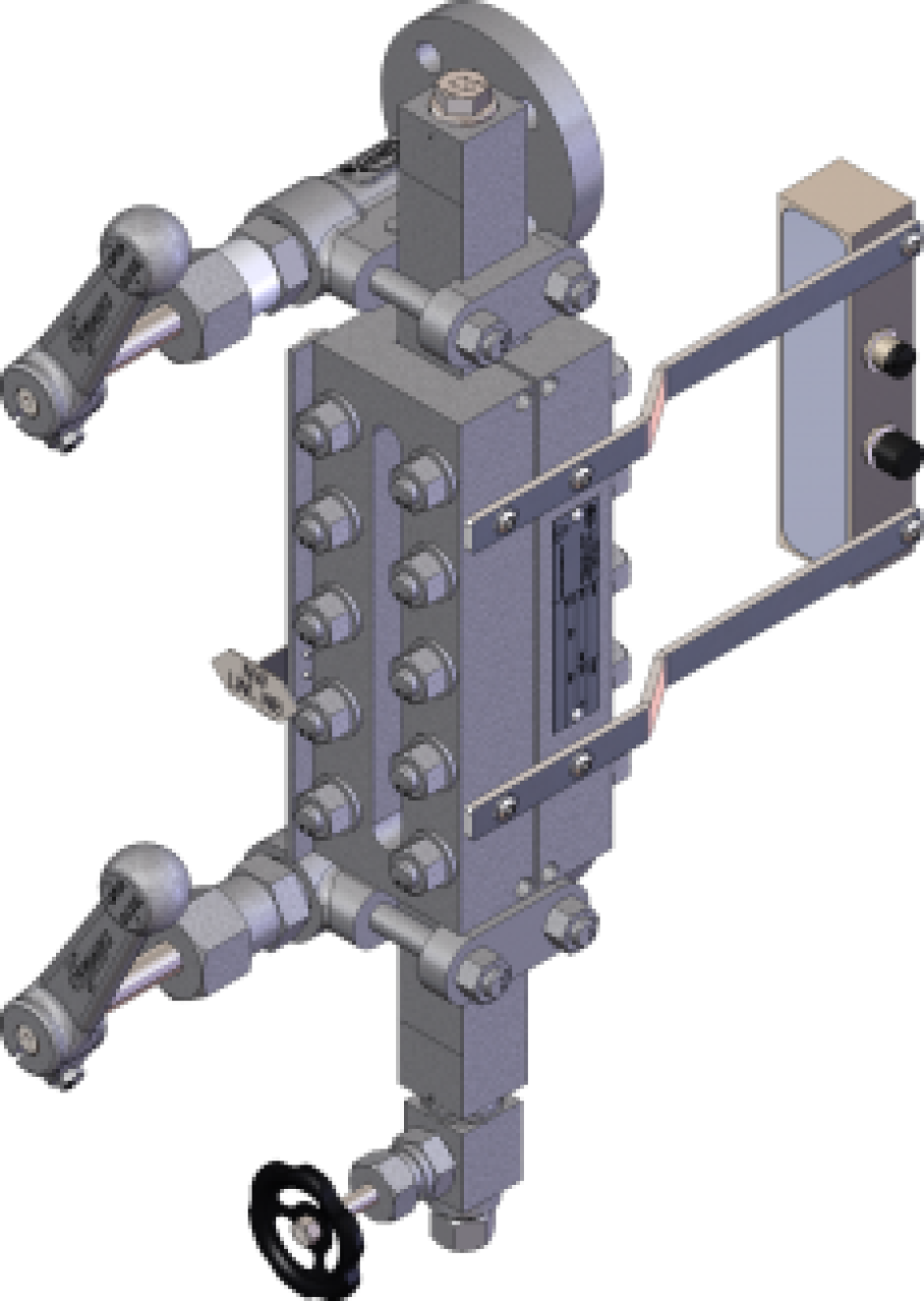

Reflex level indicators

These waterlevel indicators give a direct reading of the level of the fluid.

Due to the grooves in the glass, there is a clear light refraction so that the level is visible.

No additional light source is required to reveal the level.

Magnetic level indicators

The magnetic level indicator by means a floater with magnet ring gives you indirectly the level of tanks, reservoirs and steam boilers.

Transparant level indicators

This level indicator in combination with a light source allows a direct reading of liquid level.

Versions with glass and mica are able to PN100.

Devices with only mica can be used for pressures up to PN320.

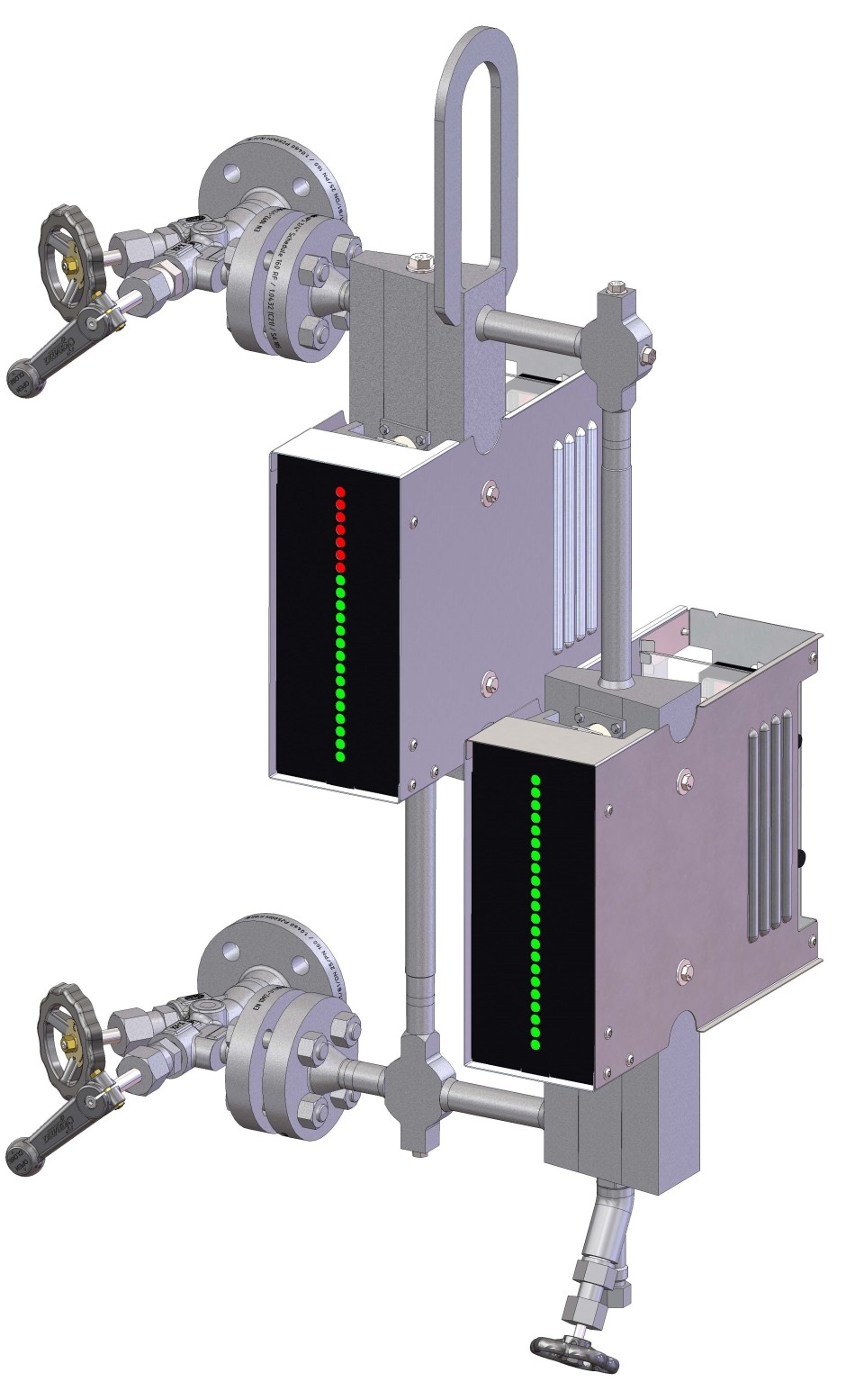

Two color level indicators

Due to the separation of light through various media, the glass gives a red color for the water and a green color for the steam, which causes an immediate indication of level.

There is also a black / white version, which is very suitable for remote transmission with a camera.

Electronic level indicators

Several horizontally disposed level probes provide an indirect level of your boiler.

This unit can be used at operating pressures up to 200 bar.